Ngokubanzi, ukuprintwa kwe-UV kubandakanya ezi ndidi zilandelayo zobuchwepheshe:

1. Izixhobo zoMthombo wokukhanya kwe-UV

Oku kuquka izibane, izixhobo zokubonakalisa ubushushu, iinkqubo zokulawula amandla, kunye neenkqubo zokulawula ubushushu (ukupholisa).

(1) Izibane

Izibane ze-UV ezisetyenziswa kakhulu zizibane zomphunga ze-mercury, eziqulathe i-mercury ngaphakathi kwityhubhu. Kwezinye iimeko, ezinye iintsimbi ezifana ne-gallium zongezwa ukulungisa i-spectral output.

Izibane ze-metal-halide kunye nezibane ze-quartz nazo zisetyenziswa kakhulu, kwaye ezininzi zisathengwa kwamanye amazwe.

Uluhlu lobude be-wavelength olukhutshwa zizibane ze-UV eziphilisayo kufuneka lube phakathi kwe-200–400 nm ukuze lusebenze kakuhle ekuphilisa.

(2) Izinto ezibonisa ukukhanya

Umsebenzi ophambili wesibonisi kukubuyisela imitha ye-UV kwi-substrate ukuze kwandiswe ukusebenza kakuhle kokuphilisa (UV Tech Publications, 1991). Enye indima ebalulekileyo kukunceda ukugcina ubushushu obufanelekileyo bokusebenza kwesibane.

IiReflectors zihlala zenziwe nge-aluminium, kwaye ukubonakalisa kufuneka kufikelele kwi-90%.

Kukho uyilo olusisiseko lwezibonisi-mbonakalo ezimbini: olugxile (oluyi-elliptical) nolungagxile (oluyi-parabolic), kunye notshintsho olongezelelweyo oluphuhliswe ngabavelisi.

(3) Iinkqubo zoLawulo lwaMandla

Ezi nkqubo ziqinisekisa ukuba imveliso ye-UV ihlala izinzile, igcina ukusebenza kakuhle kokulungisa kunye nokuhambelana ngelixa ihlengahlengisa isantya sokuprinta esahlukileyo. Ezinye iinkqubo zilawulwa ngekhompyutha, ngelixa ezinye zisebenzisa ulawulo lwe-microcomputer.

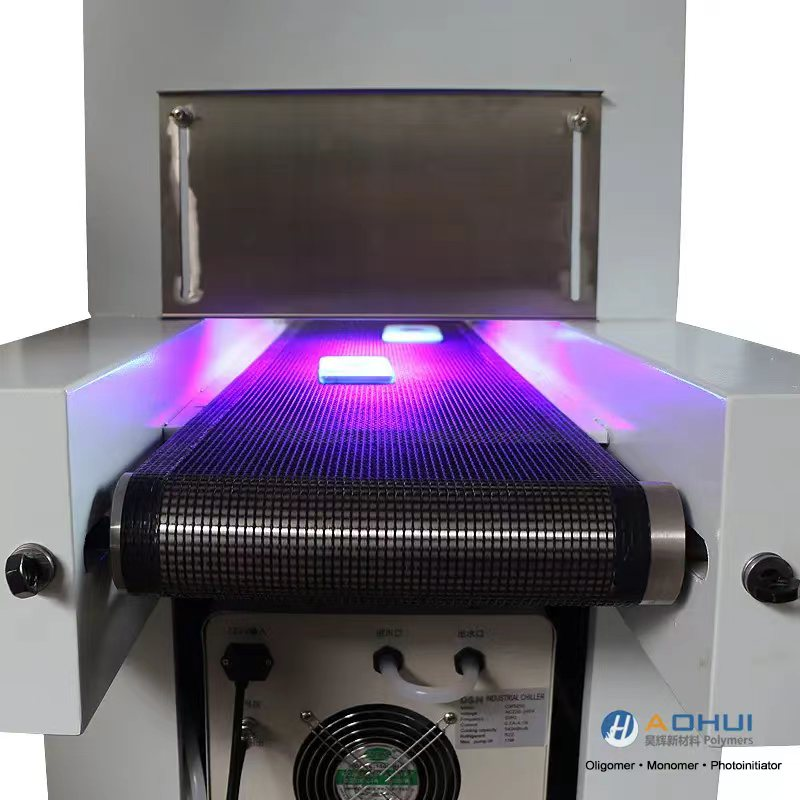

2. Iinkqubo zokupholisa

Ngenxa yokuba izibane ze-UV azikhuphi nje kuphela imitha ye-UV kodwa zikwakhupha nobushushu be-infrared (IR), izixhobo zisebenza kumaqondo obushushu aphezulu (umzekelo, ubushushu bomphezulu wezibane ezisekwe kwi-quartz bunokufikelela kumakhulu aliqela ee-degrees Celsius).

Ubushushu obugqithisileyo bunokunciphisa ixesha lokusebenza kwezixhobo kwaye bunokubangela ukwanda okanye ukuguqulwa kwe-substrate, okukhokelela kwiimpazamo zokubhalisa ngexesha lokuprinta. Ke ngoko, iinkqubo zokupholisa zibaluleke kakhulu.

3. Inkqubo yoNikezo lweInki

Xa kuthelekiswa nee-inki ze-offset eziqhelekileyo, ii-inki ze-UV zinoburhabaxa obuphezulu kunye nokungqubana okukhulu, kwaye zinokubangela ukuguguleka kwiindawo zomatshini ezifana neengubo kunye neerola.

Ngoko ke, ngexesha lokuprinta, i-inki esemthonjeni kufuneka ihlale ishukunyiswa, kwaye iirola kunye neengubo ezikwinkqubo ye-inki mazibe zizinto ezenzelwe ngokukodwa ukuprinta nge-UV.

Ukugcina uzinzo lwe-inki nokuthintela utshintsho lwe-viscosity olunxulumene nobushushu, iinkqubo zokulawula ubushushu ezijikelezayo nazo zibalulekile.

4. Iinkqubo zokusasaza ubushushu kunye nokuphuma komoya

Ezi nkqubo zisusa ubushushu obugqithisileyo kunye ne-ozone eveliswa ngexesha le-inki polymerization kunye ne-curing.

Ngokwesiqhelo ziquka injini yokukhupha umoya kunye nenkqubo yokuhambisa umoya.

[Ukuveliswa kwe-ozone kunxulunyaniswa kakhulu namaza e-UV angaphantsi kwe-~240 nm; iinkqubo ezininzi zanamhlanje zinciphisa i-ozone ngokusebenzisa imithombo ehluziweyo okanye ye-LED.]

5. Ii-inki zokuprinta

Umgangatho we-inki yeyona nto ibalulekileyo echaphazela iziphumo zokuprintwa kwe-UV. Ukongeza ekuchaphazeleni ukuveliswa kombala kunye nobungakanani obuhlukeneyo, ukuprintwa kwe-inki kumisela ngokuthe ngqo ukunamathela, amandla, kunye nokumelana nokukrweleka koshicilelo lokugqibela.

Iimpawu ze-photoinitiators kunye nee-monomers zibalulekile ekusebenzeni.

Ukuqinisekisa ukunamathelana okuhle, xa i-inki ye-UV emanzi idibana ne-substrate, uxinzelelo lomphezulu we-substrate (dynes/cm) kufuneka lube phezulu kunolo lwe-inki (Schilstra, 1997). Ke ngoko, ukulawula uxinzelelo lomphezulu we-inki kunye ne-substrate bubuchwepheshe obuphambili ekuprintweni kwe-UV.

6. Izixhobo zokulinganisa amandla e-UV

Ngenxa yokuba izinto ezinje ngokuguga kwezibane, ukuguquguquka kwamandla, kunye notshintsho lwesantya sokuprinta zinokuchaphazela ukuphiliswa, kubalulekile ukujonga nokugcina amandla e-UV ezinzile. Ke ngoko, iteknoloji yokulinganisa amandla e-UV idlala indima ebalulekileyo ekuprintweni kwe-UV.

Ixesha leposi: Disemba-30-2025