Isizukulwana esitsha se-UV-enyanga ii-silicones kunye ne-epoxies ziya zisetyenziswa kakhulu kwi-automotive kunye ne-electronic applications.

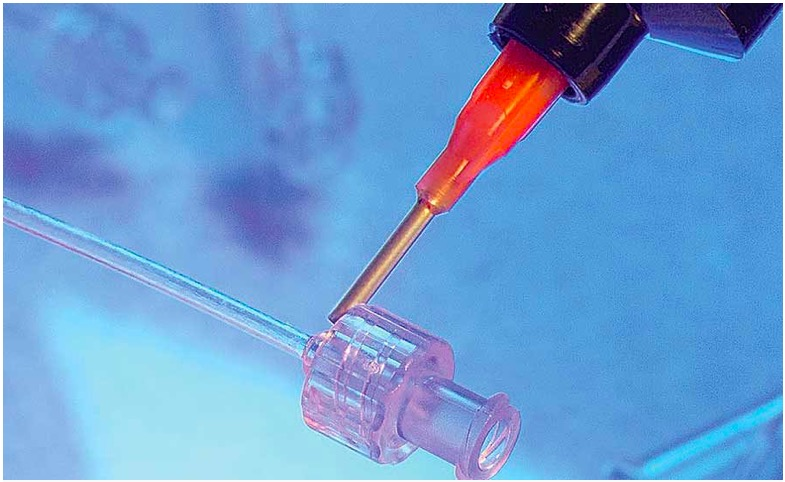

Zonke izenzo zobomi zibandakanya utshintshiselwano: Ukufumana ibhenefithi enye ngeendleko zomnye, ukuze kuhlangatyezwane kakuhle neemfuno zemeko ekhoyo. Xa imeko ibandakanya ukudibanisa okuphezulu, ukutywinwa okanye i-gasketing, abavelisi baxhomekeke kwi-Adhesives ye-UV ngenxa yokuba bavumela ukufunwa kunye nokunyangwa ngokukhawuleza (i-1 ukuya kwi-5 imizuzwana emva kokuvezwa kokukhanya).

I-trade-off, nangona kunjalo, kukuba ezi zincamathelisi (i-acrylic, i-silicone kunye ne-epoxy) zifuna i-substrate ecacileyo ukuze ibophe ngokufanelekileyo, kwaye zibiza kakhulu ngaphezu kwe-adhesives ephilisa ngezinye iindlela. Nangona kunjalo, abavelisi abaninzi kwimizi-mveliso emininzi baye benza olu rhwebo ngolonwabo amashumi eminyaka. Iinkampani ezininzi ngakumbi ziya kwenza oko kwikamva elibonakalayo. Umahluko, nangona kunjalo, kukuba iinjineli ziya kuba lula ukusebenzisa i-silicone okanye i-epoxy UV-ancamathiselelo yokunyanga, njengaleyo isekwe kwi-acrylic.

"Nangona senze i-silicones yonyango ye-UV kule minyaka ilishumi idlulileyo okanye kunjalo, kule minyaka mithathu idlulileyo kuye kwafuneka ukuba siqinise iinzame zethu zokuthengisa ukuze sihambisane nemfuno yentengiso," utshilo uDoug McKinzie, usekela mongameli weemveliso ezikhethekileyo kwiNovagard Solutions. "Intengiso yethu ye-silicone yonyango lwe-UV inyuke ngeepesenti ezingama-50 kule minyaka imbalwa idlulileyo. Oku kuya kunciphisa abanye, kodwa sisalindele ukukhula okuhle kwiminyaka eliqela ezayo."

Phakathi kwabasebenzisi abakhulu bee-silicones zokunyanga i-UV zii-OEM zemoto, kunye neTier 1 kunye neTier 2 ababoneleli. Umthengisi omnye we-Tier 2 usebenzisa i-Loctite SI 5031 sealant esuka kwi-Henkel Corp. ukuya kwi-terminal terminals kwizindlu zeemodyuli zokulawula i-electronic brake-control kunye nezinzwa zoxinzelelo lwetayara. Inkampani ikwasebenzisa i-Loctite SI 5039 ukwenza i-gasket ye-silicone ephiliswe kwi-UV ejikeleze umjikelezo wemodyuli nganye. UBill Brown, umphathi wobunjineli bezicelo ze-Henkel, uthi zombini iimveliso ziqulethe idayi ye-fluorescent ukunceda ukuqinisekisa ubukho be-adhesive ngexesha lokuhlolwa kokugqibela.

Le subassembly ke ithunyelwa kumboneleli weSigaba soku-1 ofaka amacandelo awongezelelweyo angaphakathi kwaye aqhagamshele i-PCB kwii-terminals. Isigqubuthelo sibekwe phezu kwe-perimeter gasket ukwenza itywina eliqinileyo lokusingqongileyo kwindibano yokugqibela.

Izinto zokuncamathelisa ze-epoxy ze-UV zikwasetyenziswa rhoqo kwiimoto nakwizixhobo zombane zabathengi. Esinye isizathu kukuba ezi zincamathelisi, njenge-silicones, zenziwe ngokukodwa ukuze zihambelane nobude bemithombo yokukhanya kwe-LED (320 ukuya kwi-550 nanometers), ngoko abavelisi bafumana zonke izibonelelo zokukhanya kwe-LED, njengobomi obude, ukushisa okulinganiselwe kunye nokulungelelaniswa okuguquguqukayo. Esinye isizathu ziindleko ezisezantsi zokunyanga i-UV, ngokwenza oko kube lula kwiinkampani ukurhweba ukuya kobu buchwephesha.

Ixesha lokuposa: Aug-04-2024