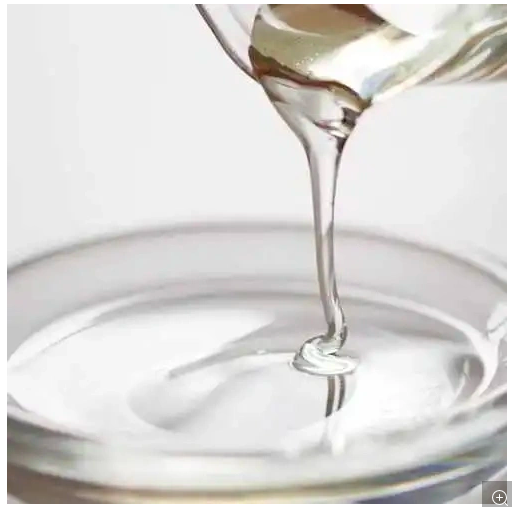

I-Vat photopolymerization, ngokukodwa i-laser stereolithography okanye i-SL/SLA, yayiyeyokuqala iteknoloji yoshicilelo lwe-3D kwimarike. UChuck Hull wayiqamba ngo-1984, wayenza ipatent ngo-1986, kwaye waseka iiNkqubo ze-3D. Inkqubo isebenzisa umqadi welaser ukwenza ipolymerize imathiriyeli ye-photoactive monomer kwivat. I-photopolymerized (iphilisiweyo) umaleko unamathela kwipleyiti yokwakha ehamba phezulu okanye ezantsi ngokuxhomekeke kwi-hardware, evumela iileya ezilandelelanayo ukuba zenze. Iinkqubo ze-SLA zinokuvelisa iindawo ezincinci kakhulu nezichanekileyo zisebenzisa i-laser beam encinci yedayamitha, kwinkqubo eyaziwa ngokuba yi-micro SLA okanye µSLA. Basenokuvelisa iindawo ezinkulu kakhulu besebenzisa idiameter enkulu yomqadi kunye namaxesha amade emveliso, ngaphakathi kwemithamo yokwakha enokulinganisa ngaphezulu kwee-cubic metres ezimbini.

Umshicileli we-SLA-1 Stereolithography (SLA), umshicileli wokuqala we-3D worhwebo, waziswa yi-3D Systems ngo-1987.

Kukho iindidi ezininzi zetekhnoloji ye-vat photopolymerization ekhoyo namhlanje. Eyokuqala eyavela emva kwe-SLA yayiyi-DLP (i-Digital Light Processing), eyaphuhliswa yi-Texas Instruments kwaye yaziswa kwimarike kwi-1987. Esikhundleni sokusebenzisa i-laser beam ye-photopolymerization, iteknoloji ye-DLP isebenzisa iprojekti yokukhanya kwedijithali (efana neprojekti yeTV eqhelekileyo). Oku kuyenza ikhawuleze ngaphezu kwe-SLA, njengoko ikwazi ukwenza ifotopolymerize umaleko wonke wento ngaxeshanye (ebizwa ngokuba yinkqubo “yeplanar”). Nangona kunjalo, umgangatho wamalungu uxhomekeke kwisisombululo seprojekti kunye nokwehla njengoko ubungakanani bukhula.

Njengokukhutshwa kwezinto eziphathekayo, i-stereolithography iye yafikeleleka ngakumbi ngokufumaneka kweenkqubo eziphantsi kweendleko. Iinkqubo zokuqala zexabiso eliphantsi zazisekelwe kwi-SLA yokuqala kunye neenkqubo ze-DLP. Nangona kunjalo, kwiminyaka yakutshanje, isizukulwana esitsha se-ultra-low-cost-cost, i-compact systems esekelwe kwimithombo yokukhanya ye-LED / LCD iye yavela. I-evolution elandelayo ye-vat photopolymerization yaziwa ngokuba yi-"continuous" okanye "layerless" photopolymerization, ngokuqhelekileyo isekelwe kwi-architecture ye-DLP. Ezi nkqubo zisebenzisa i-membrane, ngokuqhelekileyo ioksijini, ukunika amandla amazinga okuvelisa ngokukhawuleza kunye nokuqhubekayo. Ilungelo elilodwa lomenzi wechiza lolu hlobo lwe-stereolithography yaqala ukubhaliswa ngo-2006 ngu-EnvisionTEC, inkampani ye-DLP ethe yaphinda yabizwa ngokuba yi-ETEC, emva kokufunyanwa kwayo yi-Desktop Metal. Nangona kunjalo, iCarbon, inkampani esekwe eSilicon Valley, yayiyeyokuqala ukuthengisa le teknoloji ngo-2016 kwaye sele izinzile njengenkokeli kwimarike. Itekhnoloji yeCarbon, eyaziwa ngokuba yi-DLS (iDigital Light Synthesis), ibonelela ngamazinga aphezulu kakhulu emveliso kunye nokukwazi ukuvelisa iinxalenye ezinemathiriyeli eyomeleleyo, ukudibanisa i-thermosets kunye neefotopolymers. Ezinye iinkampani, ezifana ne-3D Systems (Figure 4), Imvelaphi (ngoku inxalenye ye-Stratasys), i-LuxCreo, i-Carima, kunye nabanye, baye bazisa ubuchwepheshe obufanayo kwiimarike.

Ixesha lokuposa: Mar-29-2025